-

Casing End…

For safety reasons carrier pipes are installed inside casing sleeves wherever pipes are being laid under roads, railways or rivers. It is important that the annular space is kept dry in order to reduce the risk of corrosion.

Used to seal the annular spaces between the casing and carrier pipe to prevent the ingress of moisture, water and other foreign objects.

Flexible to adapt to the thermal expansion and contraction of the casing and carrier pipe.

Flexible to adapt to the non-concentricity between the casing and carrier pipe.

It has excellent physical properties, an optimal ageing resistance and chemical resistance, even at low temperatures

Easy and quick to installDownload product brochure

-

Casing spa…

Casing spacers are used for insulating support and protection between carrier pipelines and casing pipelines when pipelines cross roads, railways, rivers and other obstacles. They are mainly made of high-density polyethylene, adding reinforcing agents, toughening agents, etc. . It has excellent insulation properties, low temperature resistance, corrosion resistance, anti-skid and wear resistance, pressure resistance, impact resistance and other advantages. It is widely used in oil, natural gas, petrochemical, electric power, metallurgy, water supply and other fields.

Casing spacers produced by our company are suitable for various steel pipes, PE/PVC pipes, and ductile iron pipes. The pipe diameter range is 60~1220mm. The skid heights are mainly 15mm, 25mm, 36mm, 50mm, and 75mm. They can also be customized according to the requirements.Download product brochure

-

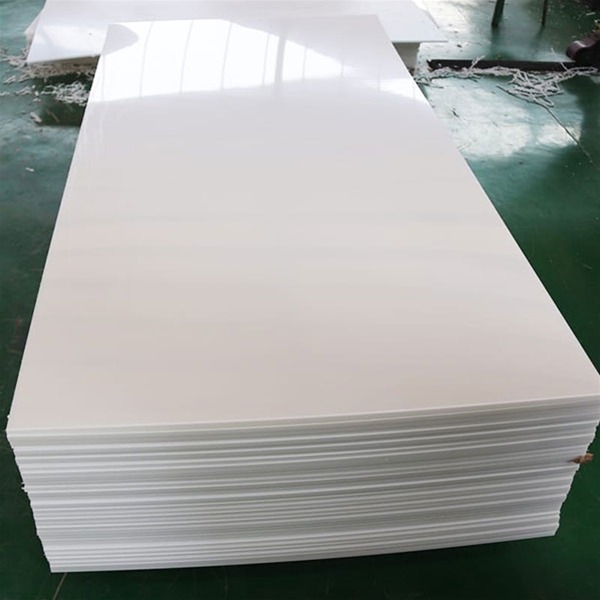

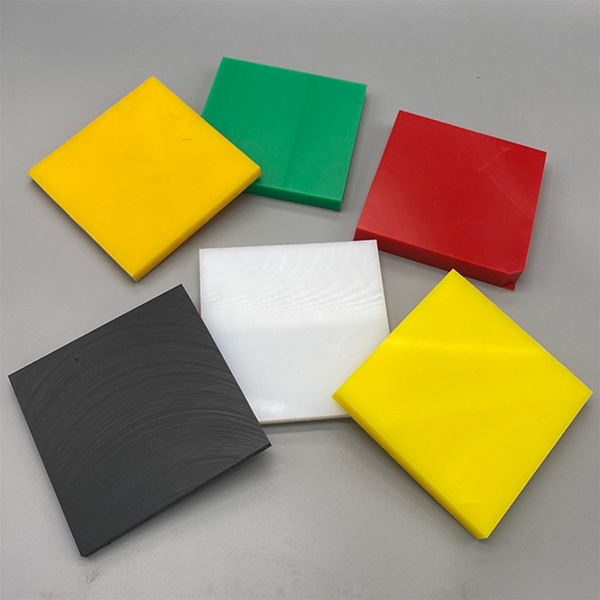

PP sheet

PP sheet (polypropylene sheet) is a semi-crystalline thermoplastic material manufactured using the catalytic polymerization process of propylene. PP can be modified and customized by adding glass fiber, metal additives or thermoplastic rubber to meet unique needs. Application requirements, such as glass fiber reinforced PP board (FRPP board), PP modified board, PPH board, PP flame retardant board, IM-PP board, etc.

Regular size: 1000×2000; 1220×2440; 1300×2000; 1500×3000; 2000×3000; Width: up to 3 meters; Thickness: 2-30mm; Length: can be customized;

Color: translucent, milky white, computer gray, porcelain white, beige, black, blue, gray, etc.

Features: Small density, light weight, low cost and long life; Easy to weld and process; Non-toxic and odorless, safe and environmentally friendly; Heat-resistant, no deformation; Resistant to chemical corrosion; Impact resistant and not easy to crack; Excellent dielectric and insulation properties; High hardness and strength;

Application scope: electroplating tanks, acid and alkali resistant environmental protection equipment, solar photovoltaic equipment, wastewater and gas emission equipment, washing towers, clean rooms, food and medicine, breeding water tanks, building ventilation ducts, semiconductors and related industrial equipment, stamping plates, stamping mattresses boards, control cabinets, etc. -

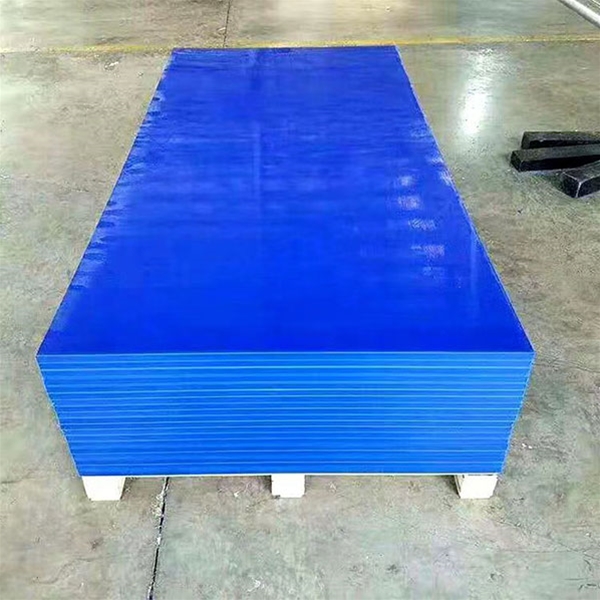

PE sheet

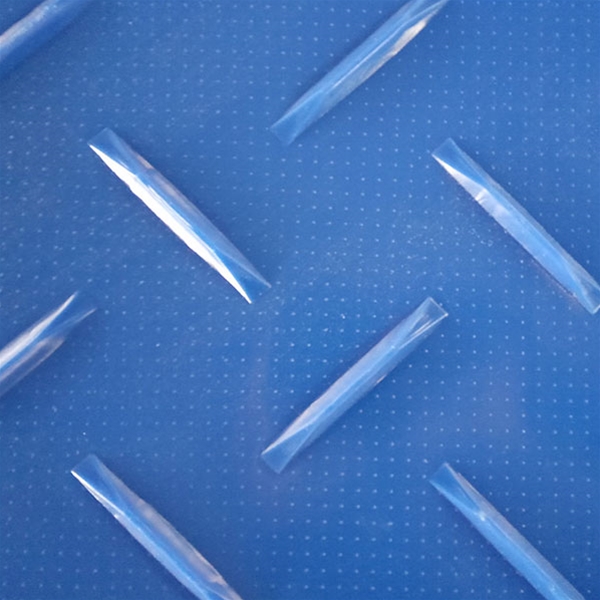

PE sheet (polyethylene sheet) is a highly crystalline, non-polar thermoplastic resin whose surface can be filled, embossed, or frosted. PE can be modified and customized by adding glass fiber, metal additives or thermoplastic rubber to meet unique application requirements, such as glass fiber reinforced PE boards, PE modified boards, and PE flame retardant boards.

Regular size: 1000×2000; 1220×2440; 1300×2000; 1500×3000; 2000×3000; Width: up to 2m ;Thickness: 3-25mm;Length: Can be customized according to user requirements

Color: milky white translucent, black, blue, etc.

Features: Small density, light weight, low cost and long life; Good electrical insulation; Good resistance to chemical corrosion, especially solvents and acids and alkalis. It is resistant to low temperatures and has excellent toughness and elastic strength at low temperatures. Good wear resistance; Easy to weld and process; Non-toxic and harmless, can come into contact with food.

Applications: chopping boards, cutting boards, gears, rollers, bearings, wear-resistant linings, conveying equipment accessories, medical instrument components, seals, cutting boards, sliding profiles. Widely used in chemical industry, machinery, chemical industry, electric power, clothing, packaging, food and other industries. -

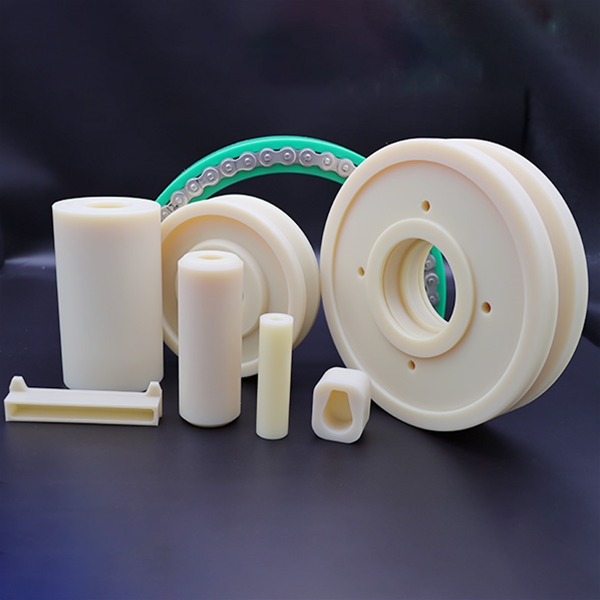

Ultra-high…

Ultra-high molecular weight polyethylene (UHMWPE) is a thermoplastic engineering plastic with excellent comprehensive properties. It is usually composed of ultra-high molecular weight polyethylene powder with an average molecular weight of more than 1.5 million and appropriate additives (such as glass beads, glass fiber, mica, Talcum powder, etc. can improve hardness, stiffness and temperature resistance; molybdenum disulfide, silicone oil and special wax can reduce the friction factor, thereby further improving self-lubrication; carbon black or metal powder can improve antistatic properties, electrical conductivity and heat transfer. ; Flame retardant or masterbatch, boron carbide powder and lead powder, etc.) are filled, blended and modified, and then sintered and pressed under high temperature and high pressure. Its basic characteristics are wear resistance, impact resistance, self-lubrication, corrosion resistance, and With comprehensive properties such as impact energy absorption, low temperature resistance, hygienic and non-toxic, not easy to adhere, not easy to absorb water, and low density, it is widely used in Conveying, food, papermaking, textiles, construction, chemical industry, coal mines, power plants, ports, sports, medical care, etc. industry.

-

Special-sh…

-

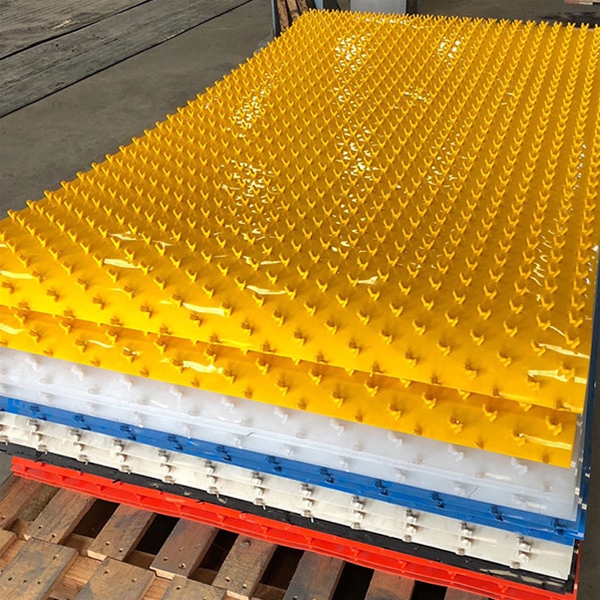

Concrete P…

Concrete Protection Liners (CPL) are made of HDPE materials which provide excellent protection of concrete structures from abrasion and corrosion. This product offers a complete, premium-quality selection of plastic liners that provide perfect protection for concrete. The main focus here is on protecting concrete against environmental influences and aggressive or abrasive media, in order to improve the service life of concrete works. The specially designed Ultra Grip V anchoring studs, which are embedded in the concrete, provide a superior mechanical connection between the concrete and the liner.

Features

Effective protection for concrete is ensured by the combination of the benefits of special thermoplastic liners (flexible, ductile, no corrosion) with those of concrete (high strength, high stiffness).

The concrete is effectively protected thus prolonging the building’s service life. Absolute mechanical anchoring and bridging of cracks in concrete, as well as excellent shear and impact strength and the durability of the liners for concrete protection are just a few of the many benefits.Download product brochure

-

Ground pro…

Ground protection mats, also known as ground mats, construction mats, temporary road mats, access mats or heavy-duty mats, are portable platforms designed to protect the ground and prevent damage to sensitive surfaces during construction, landscaping, oil and gas projects, events, utility maintenance, or other heavy-duty activities. The mats are made of durable materials like HDPE or UHMWPE that can withstand heavy loads and adverse weather conditions.

It provides a stable and solid surface for vehicles and machinery to operate on, especially in soft or uneven terrains like mud, sand, or grass. Not only do ground protection mats protect the ground, but they also enhance worksite safety by providing traction and stability for equipment and workers. They can prevent machinery from getting stuck, slipping, or causing accidents due to unstable ground conditions.

Ground protection mats come in different sizes, and designs, depending on the specific application and load requirements. They are usually easy to install and can be connected together to create a lager surface area.

Download product brochure

Follow us

Scan and follow us